OEE Means | Full Form | Download OEE Template

OEE Means | Full Form | Download OEE Template:-

OEE Means, Overall Equipment Effectiveness. Seiichi Nakajima has invented overall equipment effectiveness in the 1960s to evaluate the manufacturing operation how effectively it is utilized.

Overall Equipment effectiveness is a methodology to measure the productivity of Process industries.

| OEE = A x P x Q (A-Availability. P-Performance. Q-Quality). OEE is the main key performance indicator for Total Productive Maintenance and also for IATF 16949. |

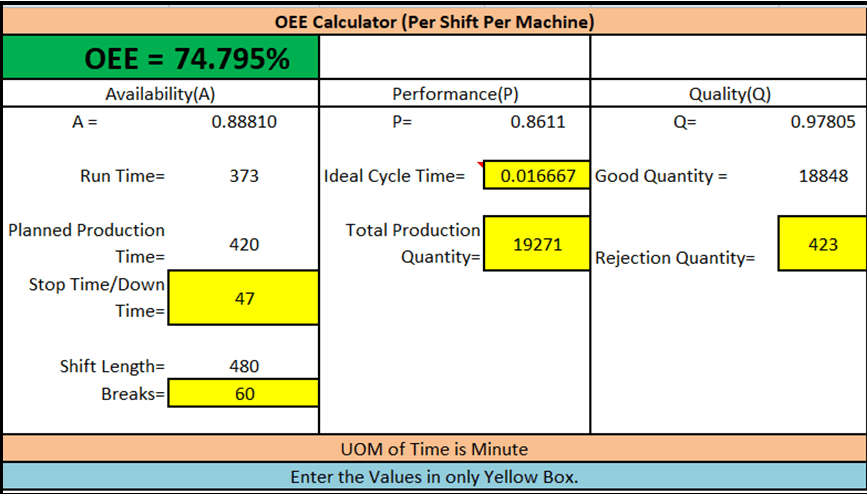

Download OEE Template (Per Shift Per Machine Basis).

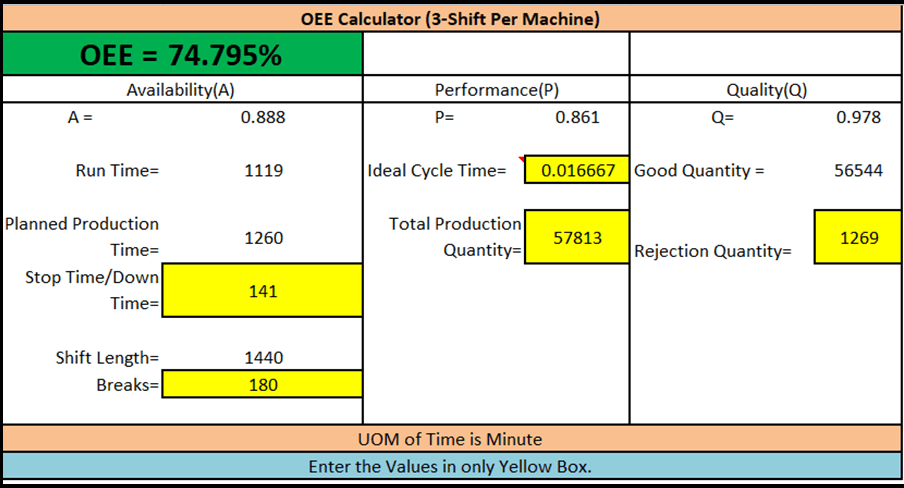

Download OEE Template (3-Shift Per Machine Basis).

How to Use the Above OEE Template:-

After downloading the above Overall Equipment Effectiveness Template, please carefully read the instructions as:-

- All yellow color boxes are changeable means you just enter the value accordingly.

- The unit of measurement of time is in minute form, so convert all time values into the minute form.

- Rather than the yellow color box, others will calculate automatically.

Example:-

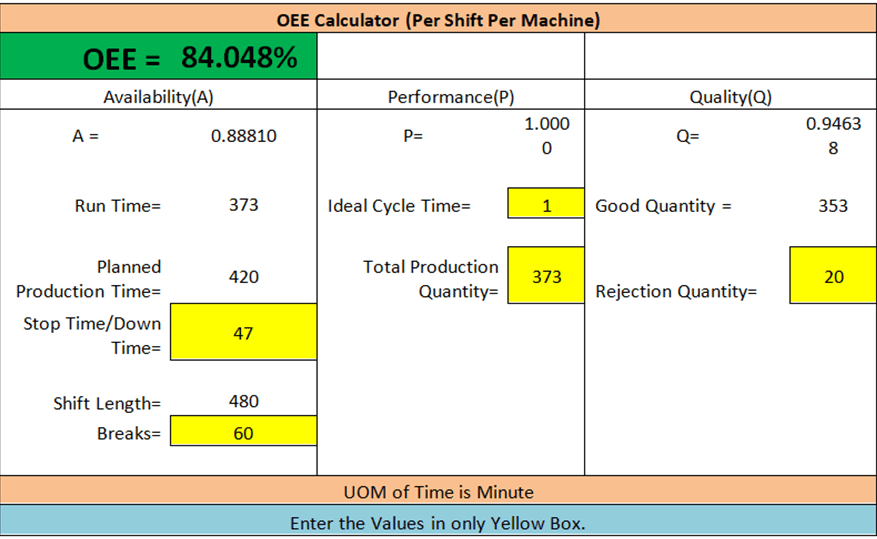

OEE calculation (Per Shift per Machine Basis):-

| Item | Data |

| Shift Length | 8 hours (8*60=480 Minutes) |

| Breaks ( Tea and Lunch) | 60 minute |

| Downtime | 47 Minutes |

| Ideal Cycle Time | 1.0 Minute |

| Total Production | 373 Pieces |

| Reject Quantity | 20 Pieces |

OEE Calculator (Per Shift Per Machine)

OEE = 84.048%

Availability(A) Performance(P) Quality(Q)

A = 0.88810, P= 1.0000, Q= 0.94638

Run Time= 373, Ideal Cycle Time= 1 , Good Quantity = 353

Planned Production Time= 420, Total Production Quantity= 373

Rejection Quantity= 20

Stop Time/Down Time= 47

Shift Length= 480

Breaks= 60

UOM of Time is Minute.

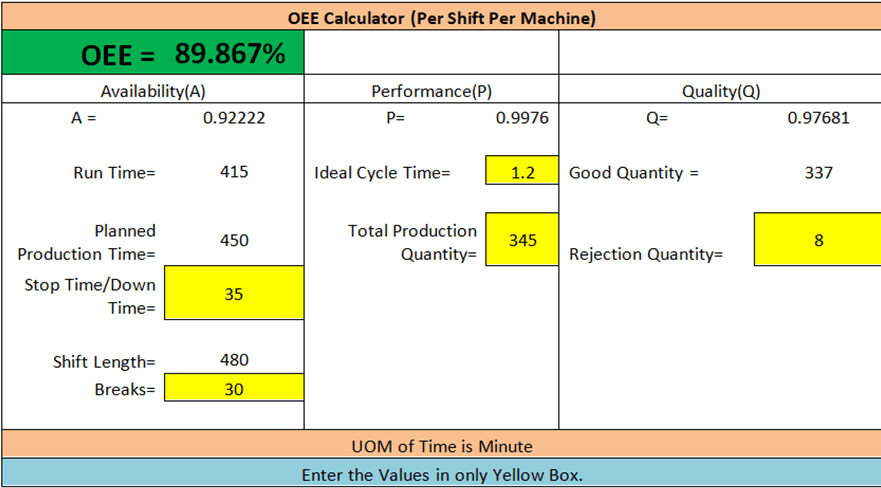

Example 2:-

| Item | Data |

| Shift Length | 8 hours (8*60=480 Minutes) |

| Breaks ( Tea and Lunch) | 30 minute |

| Downtime | 35 Minutes |

| Ideal Cycle Time | 1.2 Minute |

| Total Production | 345 Pieces |

| Reject Quantity | 8 Pieces |

Overall Equipment Effectiveness Calculator (Per Shift Per Machine)

Overall Equipment effectiveness = 89.867%

Availability(A) Performance(P) Quality(Q)

A = 0.92222 ,P= 0.9976 ,Q= 0.97681

Run Time= 415 ,Ideal Cycle Time= 1.2 ,Good Quantity = 337

Planned Production Time= 450 ,Total Production Quantity= 345

Rejection Quantity= 8

Stop Time/Down Time= 35

Shift Length= 480

Breaks= 30

UOM of Time is Minute.

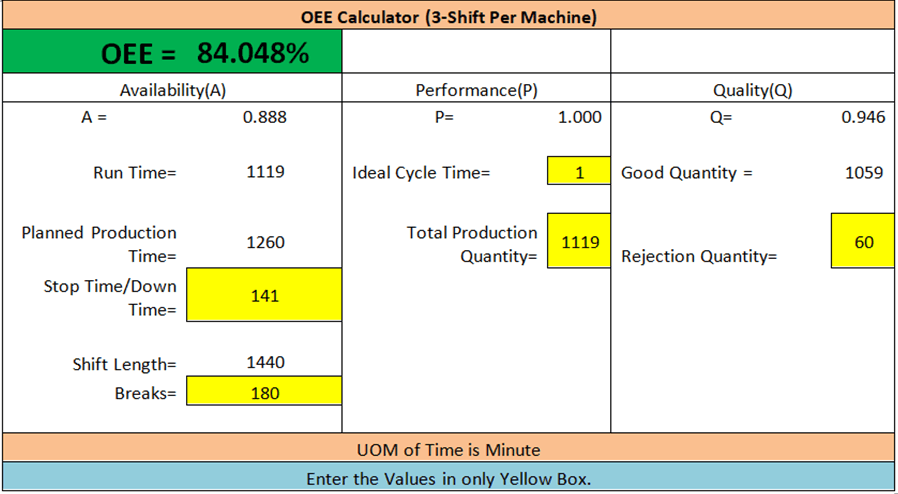

OEE calculation (3-Shift per Machine Basis):-

| Item | Data |

| Shift Length(3-Shift) | 24 hours (24*60=1440 Minutes) |

| Breaks ( Tea and Lunch) | 180 minute |

| Downtime | 141 Minutes |

| Ideal Cycle Time | 1.0 Minute |

| Total Production | 1119Pieces |

| Reject Quantity | 60 Pieces |

Overall Equipment Effectiveness Calculator (3-Shift Per Machine)

Overall Equipment Effectiveness = 84.048%

Availability(A) Performance(P) Quality(Q)

A = 0.888, P= 1.000, Q= 0.946

Run Time= 1119 , Ideal Cycle Time= 1 ,Good Quantity = 1059

Planned Production Time= 1260, Total Production Quantity= 1119 Rejection Quantity= 60

Stop Time/Down Time= 141

Shift Length= 1440

Breaks= 180

UOM of Time is Minute.

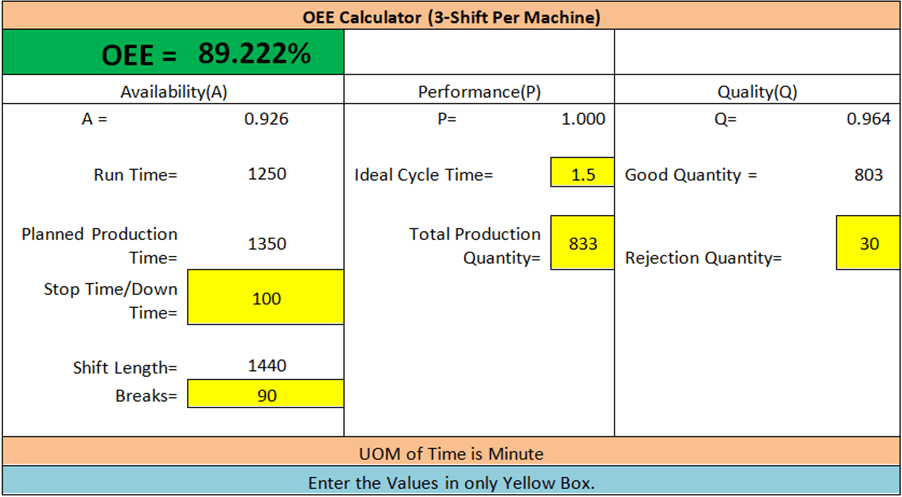

Example 2:-

| Item | Data |

| Shift Length(3-Shift) | 24 hours (24*60=1440 Minutes) |

| Breaks ( Tea and Lunch) | 90 minute |

| Downtime | 100 Minutes |

| Ideal Cycle Time | 1.5 Minute |

| Total Production | 833Pieces |

| Reject Quantity | 30 Pieces |

Overall Equipment Effectiveness Calculator (3-Shift Per Machine)

OEE = 89.222%

Availability(A) Performance(P) Quality(Q)

A = 0.926, P= 1.000 , Q= 0.964

Run Time= 1250 , Ideal Cycle Time= 1.5 ,Good Quantity = 803

Planned Production Time= 1350, Total Production Quantity= 833 Rejection Quantity= 30

Stop Time/Down Time= 100

Shift Length= 1440

Breaks= 90

UOM of Time is Minute.

Now, I hope it’s clear to all “how to calculate the overall equipment effectiveness” by using the above Template. If you would like to calculate manually and would like to know more about the formula then click here.

I hope you understand the concept of OEE, but I would like to request you calculate the Rate of Quality of the below conditions and match your answer with our solution.

suppose a company produced 50000 quantities of product A and rejected quantities are 200 nos. Calculate the rate of quality and rate of quality percentage.

Solution:

Total parts Produced = 50000 nos

Total parts rejected = 200 nos

Rate of quality = [Total parts produced – Total parts rejected] / Total parts produced

= Good parts produced / Total parts produced.

ROQ = [50000-300]/50000

= 49700/50000

0.994

ROQ = 0.994

ROQ% = ROQ x 100

=0.994 x 100

= 99.4%

Similar and Useful Articles:

OEE Calculation-How To Calculate OEE (Overall Equipment Effectiveness) with Example.

Histogram Example | Foundry Industries Examples.

Histogram Template with example | Download