Pull Production System | Concept

Pull Production System | Concept

Pull Production System: Hello Reader! Today we will discuss the most popular tools or principles of TPS (Toyota Production System) is namely called PPS (Pull Production System). Mr. Taiichi Ohno had implemented this concept in the TPS system in Toyota Company. PPS is nothing but it is a manufacturing system in which production is based on the actual demand of customers (OEM, Tred, T-1, or end-user, etc.). The main purpose of a pull-production system is JIT and Low Inventory Production.

Know More: Toyota Production System History, Tools & Principles.

Pull Production System (PPS):

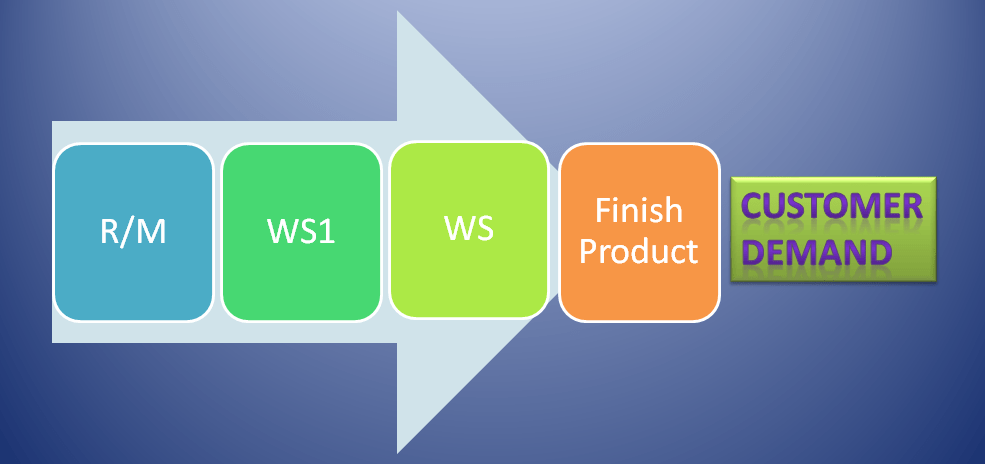

Pull production is not so easy to implement, Toyota Company took 20 years to effectively implement the PPS. In Traditional manufacturing products are processed in batches of materials from one workstation (WS) to another and in each work station executes much work with several types of material flow, because there are many jobs that need to be executed at each workstation or machine, so it is difficult to synchronize the flow of materials.

Later it would result in large amounts of in-process inventory at various workstations. But in the pull production system, the manufacturing unit develops a system that will indicate the demand of material flow in each stage so that there will eliminate the need for large amounts of inventory and also need to be implemented the KANBAN system to coordinate the flow of materials between the work station in such a way that the inventory will minimum or low in each stage i.e. in any stage of the process, or finish product stage. It’s just following the JIT (just-In-Time) Production.

Note;

Companies or manufacturing units that are not following the PPS may hold a high inventory, which is a big challenge and business risk in the manufacturing industry. In 2019, the Automobile industry is suffering and facing the problem may be due to the market inventory of finished products in various stages. Always it is better to follow the PPS system. Manufacture the Products as per market demand or Customer demand.

Useful Articles:

Error Proofing Understanding & Implementation of IATF 16949 Clauses 10.2.4

Swot Analysis of a Company Challenges

Pareto Chart Example of Manufacturing Units

Histogram Example | Foundry Industries Examples

Download QA & QC Tools Formats

Thank you for reading…Keep visiting Techiequality.Com

Popular Post: