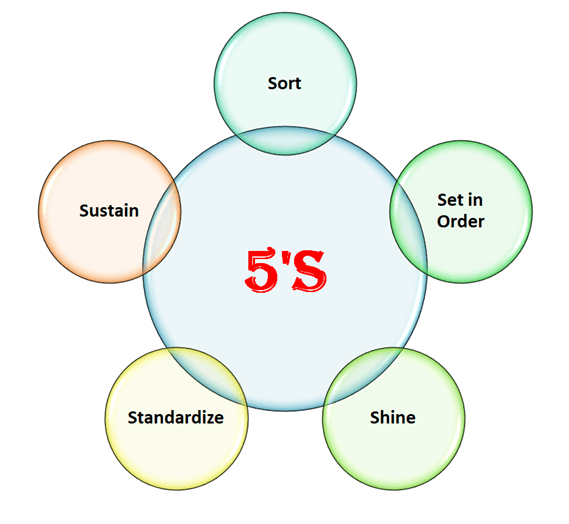

5’S Concept | What are 5’S?

Hi readers! today we will discuss a popular and important topic that is widely used in the industry i.e. 5’S Concept

What is 5’S Concept

5’s are the techniques for organizing the work effectively and safely. It helps people to do their jobs without wasting time or injury. 5’S is the base pillar of TPM (Total productive maintenance) and TPS (Toyota Production System).

What are 5’S?

| Five Japanese words | In English |

| 1-S: Seiri | 1-S: Sort |

| 2-S: Seiton | 2-S: Set in Order |

| 3-S: Seiso | 3-S: Shine |

| 4-S: Seiketsu | 4-S: Standardize |

| 5-S: Shitsuke | 5-S: Sustain |

History:

The concept 5’S was initiated as part of the TPS [Toyota Production System] at the Toyota Motor Company in the early and mid-20th century. This system is often used in Lean manufacturing and TPM [Total Productive Maintenance].

Advantages of 5’S Concept:

- Easy Accessing.

- Better work environment.

- Reduced costs

- High quality

- Increased productivity

- A safer work environment

Illustration of 5’S:

1-S: Sort:

The first step of 5’S is the “Sort”, simply in this process, we have to remove the unwanted materials and to determine what needs to be present. If required for any situation to take the decision together with the lime manager at that situation we can use the Tag system (Red tag and yellow tag).

The below questions will help you to do the sorting in your work areas.

Q1: Does it really need to be here or not?

Q2: What is the tenacity of this item?

Q3: How often is it used?

Ask these questions during the sorting operation and make also a work layout.

2-S: Set in Order:

It means neatness. Always follow the golden rule of “Place for everything and everything in its place”

Follow the below steps to “set in order”:

- Identify each and every item.

- Lay down the Work layout of each workstation/zone.

- Keep the items nearest to the point of use.

- Ensure easy accessibility, and easy retrieval, Minimize the inventories.

- Mark the gangway and foot stoppage on the shop floor for safe and easy movement of men and materials.

In this way, you can easily store the essential material in the appropriate location. You will get so many advantages after the effective implementation of 2-S as;

- Improves workplace utilization.

- Reduce the inventory level.

- Create a safe work environment.

- Helps reduce time consumed in searching for materials for use.

3-S: Shine:

Cleaning is not a job; it is a frame of mind.

In many places, cleaning is considered as a separate job. A workman feels that it is not his job to clean the machine. So to overcome their thinking, the culture has to come from top management to the bottom-most designation. First of all, we have to clean our table, and chairs without waiting for the sweeper or peon. We have to follow the three-step approach as Macro level, Individual Level, and Micro Level. During the 3-S operation, we can also put the tag, if we will find the Problems like electrical, mechanical, civil, etc. in the workplace.

4-S: Standardize:

The 4-S is the Standardization, this means ensuring whatever cleanliness and orderliness have been achieved through improvement in Sort, Set in Order, and Shine have to be standardized.

You can follow the below-mentioned methodology to achieve standardization:

- Prepare a 5-S SOP or Manual.

- Lay down the Work Layout of every work zone.

- Standardize the cleaning kits.

- Visual management.

5-S: Sustain:

This is the last step but not the least, it’s a Sustain.

Define the rules and responsibilities of each zone member and make them aware of the 5-S benefit. If some practices are not followed, analyze the root cause of failure. Carry out the 5-S audit on a periodic basis and appreciate the best zone.

Useful Articles:

Thank you for reading…..Keep visiting Techiequality.com

I think the article “5’S Concept” is useful to you…If you require any further information, feel free to contact me.

Popular Post: