How to calculate process performance (Pp & Ppk)?

How to calculate process performance (Pp & Ppk)?

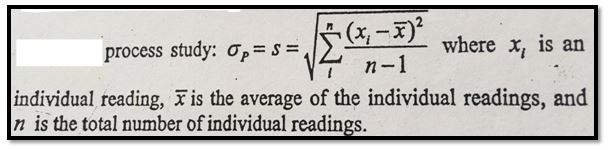

Hi Readers! Today we will discuss on How to calculate process performance? The Pp (Process Performance) provides a measure of how well the process will satisfy the variability requirements. The Index of process performance is termed as Ppk. It takes the process location as well as the performance into account. Before discussing on calculation part, I would request my all readers kindly go through the formula of Pp and Ppk. And if you are interested in downloading our free Excel template then click on the below download link.

DOWNLOAD Excel Template/Format of Pp & Ppk calculation with Example.

| How to use |

The formula of Pp (Process Performance):

Pp = ((USL-LSL)/ (6 X S))

[Where USL=Upper specification limit, LSL=Lower specification limit, and S= Standard Deviation]

Formula of Ppk (Process Performance Index):

Ppk = Minimum of PPU or PPL

PPU= ((USL-Average of average)/ (3 X S))

PPL= ((Average of average-LSL)/ (3 X S))

Note: Pp ≥ Ppk.

Example:

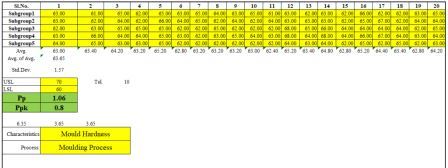

A Company ZYX Ltd has collected 100 numbers readings of Pouring temperature having the specification range from 1420°C to 1400°C and calculates the process performance and its index to know the performance of a process, which means how well it satisfies the variability requirement. So we have the 100 numbers of reading and we will calculate the Pp & Ppk value;

| Sl. No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| SG1 | 1409 | 1410 | 1412 | 1410 | 1408 | 1414 | 1413 | 1411 |

| SG2 | 1408 | 1410 | 1412 | 1410 | 1408 | 1414 | 1413 | 1411 |

| SG3 | 1408 | 1409 | 1411 | 1410 | 1405 | 1413 | 1411 | 1410 |

| SG4 | 1406 | 1409 | 1410 | 1409 | 1405 | 1413 | 1411 | 1410 |

| SG5 | 1406 | 1408 | 1410 | 1409 | 1404 | 1412 | 1411 | 1410 |

Note: SG=Subgroup

| 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1413 | 1408 | 1413 | 1412 | 1410 | 1409 | 1412 | 1408 |

| 1413 | 1408 | 1413 | 1412 | 1410 | 1408 | 1412 | 1408 |

| 1411 | 1405 | 1411 | 1410 | 1410 | 1408 | 1411 | 1405 |

| 1411 | 1405 | 1411 | 1410 | 1409 | 1406 | 1410 | 1405 |

| 1410 | 1404 | 1411 | 1410 | 1409 | 1406 | 1410 | 1404 |

| 17 | 18 | 19 | 20 |

| 1412 | 1408 | 1410 | 1408 |

| 1412 | 1408 | 1410 | 1408 |

| 1411 | 1405 | 1410 | 1405 |

| 1410 | 1405 | 1409 | 1405 |

| 1410 | 1404 | 1409 | 1404 |

Calculation:

Pp=20/ (6 X 2.69) =1.24

PPU= (1420-1409.04)/ (3 X 2.69) =1.36

PPL= (1409.04-1400)/ (3 X 2.69) =1.12

Sample Format:

Useful Articles:

Quality at the source | Steps to Implement It

Pull Production System | Concept

Free Download the QA Templates

More on TECHIEQUALITY

Thank you for reading

Popular Post